What you thought was "standard" actually needs customization

- Share

- Issue Time

- Aug 20,2025

Summary

Discover why "standard" baking equipment often requires customization — and how SamBake helps you get it right.

In the global baking industry, equipment is often seen as a "standard product" — place an order and it's ready to use. In reality, that's rarely the case. Voltage standards differ by country, tray sizes vary across markets, and every bakery has unique space limits, workflows, and brand identity. For buyers, these "small differences" often determine whether commercial bakery equipment truly fits.

Just last week, a case with a Brazilian client highlighted this again. Initial requirements and pricing were confirmed, but at the final stage the client mentioned their trays were 600×800mm — while our standard commercial deck oven fit 400×600mm. That single difference meant redesigning the oven chamber, airflow, door structure, and heating system. This is what many buyers often encounter as a "hidden customization blind spot" when purchasing rotating rack oven and other bakery equipment.

Today, as your dedicated customization advisor, SamBake will address three core questions about baking equipment customization:

When do I actually need customization?

How can I keep quality and costs under control?

How do I find the right custom manufacturing partner in China?

When Customization Becomes Essential – How to Identify Your Real Needs

In many cases, many buyers don't "intend" to request customization — their real needs already exceed standard models. Common triggers include:

Space & Layout: Limited kitchen space? Non-standard tray sizes (e.g., 600×800mm).

Structure & Material: Food-grade 304/430 stainless steel? ≥1mm thickness for durability.

Power & Configuration: Local standards (110V/220V/380V), plug types, electric or gas.

Controls & Usability: Mechanical panels vs. smart touch screens or PCB programs.

Functions & Processes: Steam system, stone baking, modular design.

Brand & Aesthetics: Custom colors, logo, or nameplate.

If your needs fall into any of the categories above, you're already in the realm of "customization."

This isn't an extra burden—it's the first step to making sure your baking equipment truly fits your business. Instead of discovering mismatches during installation or daily use and then facing costly adjustments, downtime, or even replacements, it's far smarter to customize from the start and avoid those hidden costs later on.

Of course, customization is more than just "tailor-made sizing." It can affect the production process, choice of components, and even the overall design plan. That's why pricing and lead times may differ from standard products.

Does Customization Mean Higher Costs and Longer Lead Times?

When buyers hear the word "customization," their first reaction is often:

"Does it mean the price will be higher?"

"Will the lead time be longer?"

The answer is yes—but not because suppliers are "overcharging." It's because customization itself changes the production chain and processes.

What drives the price difference?

Materials: Will it be food-grade 304 or 430 stainless steel? 0.8mm sheet or ≥1mm? Imported motors and control components? Each choice directly impacts cost.

Size: Standard products rely on fixed molds and processes. Once you move into non-standard sizes—such as larger chambers or different tray formats—it requires redesigning and adjusting production workflows.

Functions: Adding steam injection, stone decks, or modular combinations means more parts and more steps in manufacturing.

What affects the lead time?

Standard products are usually ready faster—sample units can be arranged within 7–10 days.

Deep customization requires additional design and approval steps (often 15+ days), and mass production will naturally take longer.

That's why customized equipment often comes with price and delivery variations—it's the logic of production, not arbitrary pricing. If you'd like a deeper look at what really drives oven costs, you can check our article: "The Core Factors Behind Oven Pricing."

But price isn't the only factor to consider. For long-term cooperation and real-world use, what truly impacts your business stability is quality and reliability:

High-grade materials & craftsmanship – Built to last under intensive use.

Advanced production technology – Ensures consistency from prototypes to bulk production.

Strict benchmarking – Measuring quality against leading brands like Sinmag and Kolb to guarantee top performance.

In other words, customization is not a "price game." It's a test of a manufacturer's true capability. And not every factory can deliver—especially when low MOQ,fast delivery, and high quality must all be met at the same time.

So, the real question is: What kind of factory actually has this capability?

How to Find the Right Customization Partner in China

Whether you're trying to turn an initial idea into reality or looking for a reliable manufacturer for an existing project, one common challenge always arises: small-batch, personalized customization is often hard to achieve. Many factories prefer standardized mass production to maximize efficiency and lower costs. But for customers who need to test the market or pursue differentiation, high MOQs and rigid production models can be major roadblocks.

At SamBake, we understand the importance of flexible production. From day one, we've specialized in providing customized solutions for bakery equipment. Our advantages include:

10+ Years of Customization Experience – We know how to turn your ideas into practical, market-ready products. Beyond execution, we provide professional and realistic suggestions to optimize design and functionality, helping you avoid unnecessary trial-and-error costs.

Low MOQ – Starting from Just 1 Unit – We understand the risks of new projects. That's why we offer the flexibility of one-unit minimum orders, reducing financial and inventory pressure, and allowing you to validate the market and iterate your products with minimal risk.

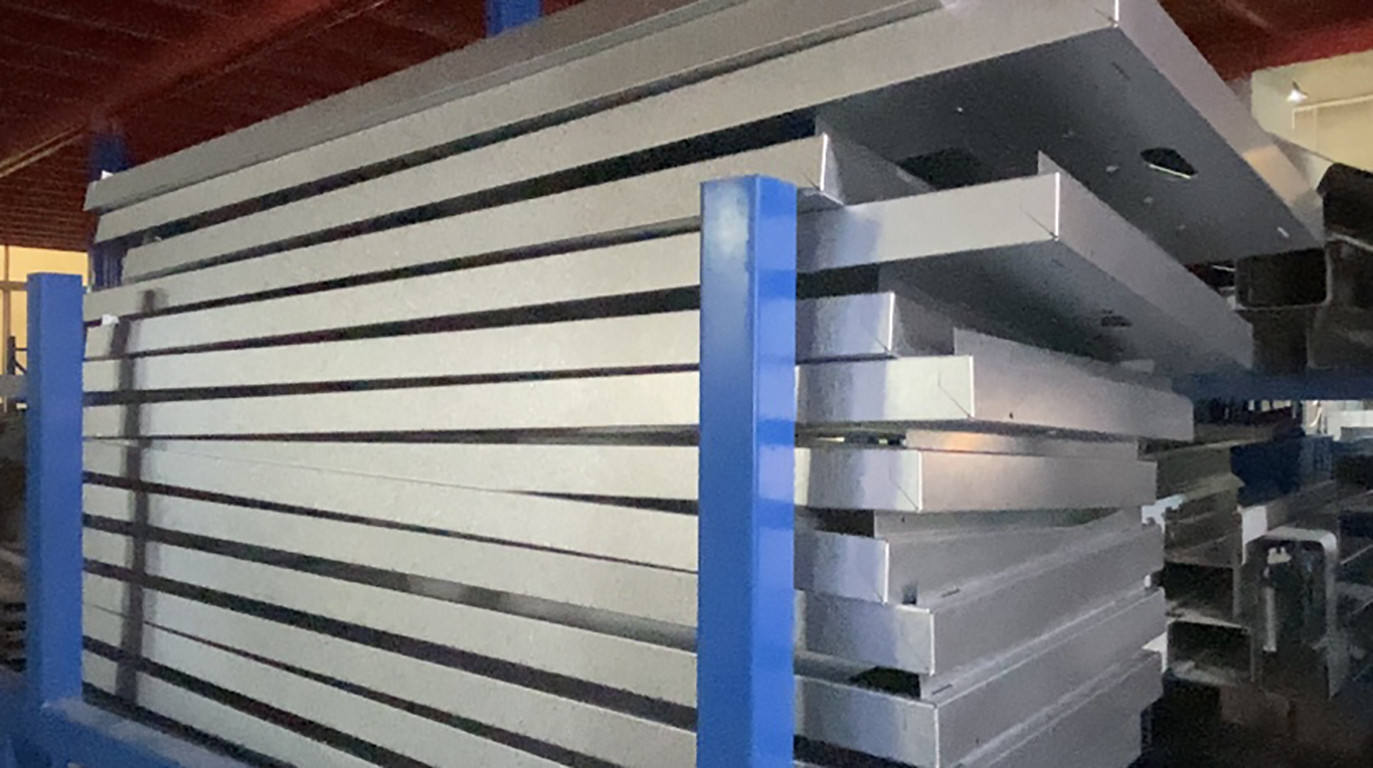

Full-Process Manufacturing with Advanced Equipment – With world-class automation like Bystronic laser cutting and Salvagnini bending systems, we can handle complex custom requirements while ensuring high precision, consistent quality, and faster delivery. Few factories in the industry can balance both flexibility and premium standards the way we do.

Whether you already have complete design drawings and need OEM (Original Equipment Manufacturing) support, or just a concept that requires ODM (Original Design Manufacturing) services to bring it to life, we can provide the right solution to grow together with your project.

If you'd like to explore further how to choose the right Chinese baking equipment manufacturer, check out our article: “How to Select the Right Baking Equipment Manufacturer in China.”

The Visible Value and the Invisible Peace of Mind

Many buyers assume customization means extra cost, but in the long run, the value it brings far outweighs the initial investment. The true meaning of customization is not just about owning a unique commercial deck oven, but about achieving higher adaptability and efficiency—fundamentally helping you avoid potential hidden costs in the future.

First, customization means your bakery equipment is designed specifically around your needs and space. It fits seamlessly into your workflow, facility layout, or special functional requirements. This avoids the common issues of buying a standard product and then having to retrofit, pause operations, or even replace it to make it work. Every modification, every downtime, and every return is a drain on both time and money. Customization is not an added burden—it's a way to prevent bigger expenses down the road.

Secondly, in today’s market where commercial deck ovens are highly homogenized, customization is the key to building brand differentiation and strengthening competitiveness. When everyone is using the same bakery equipment, your unique design, specialized features, and high adaptability become your core advantages. This not only elevates your brand image but also helps you stand out in the market by delivering unique value to your customers.

At SamBake, we believe that choosing the right customization partner is not just a purchase—it's a strategic investment in your future success.

SamBake – Your Dedicated Partner for Baking Solutions

At SamBake, we are more than just a manufacturer—we are your strategic partner. We understand that every unique idea deserves to be taken seriously, and every ambitious brand should stand out from the very beginning. Our purpose is to help turn your brand vision into reality.

This is the spirit behind our belief: "Customized Production, Unlimited Possibilities." It's not just a slogan—it's our mission. We are committed to being the most flexible and reliable customization partner, delivering solutions that truly fit your project. From your very first piece of equipment, we dedicate ourselves to helping you create distinctive products that set you apart in a highly competitive market.

Let's work together to bring your ideas to life.

Whether you'd like to explore technical details or discuss a custom solution, feel free to contact us—we're ready to help build the future of your brand together.