What Determines the Price of a Commercial Oven? SamBake Breaks It Down for You!

- Share

- Issue Time

- Jun 26,2025

Summary

Behind every oven price lies real value. SamBake reveals what truly drives cost—and offers tailored, brand-ready solutions for long-term returns and reliable performance.

Have you ever found yourself shopping for a commercial oven—only to be surprised by how much prices vary between brands? Especially SamBake—why do our ovens seem more expensive?

We understand: for every entrepreneur and brand builder, cost is a critical factor. And yes, the market offers plenty of low-price options. If you're simply looking for something that works, and long-term durability, energy efficiency, or maintenance costs aren't a concern—and if you're not aiming to build a distinctive bakery brand—then going for the lowest price might make sense.

But if you're someone with greater ambitions:

You want professional-grade baking equipment that reflects your unique brand—not just another generic machine.

You value reliability, longevity, and energy efficiency to support long-term operations.

You're looking for a true strategic partner who can help you grow locally and stand out in a competitive market.

Then SamBake warmly invites you to look deeper—and discover the real investment and lasting value behind what may seem like a higher price.

What's Beneath the Surface: The Real Costs Behind Professional Baking Equipment

Building a truly professional-grade commercial baking oven is never just about assembling materials. From rigorous material selection to precision manufacturing, from advanced control systems to every small electrical component—each step adds to the final cost, and more importantly, determines how well the oven will perform, how long it will last, and what it says about your brand.

We often compare the price of a commercial oven to an iceberg: the visible price is only what you see above the surface. What truly matters—the long-term stability, efficiency, and reliability—lies beneath the surface, where SamBake invests heavily to deliver lasting value.

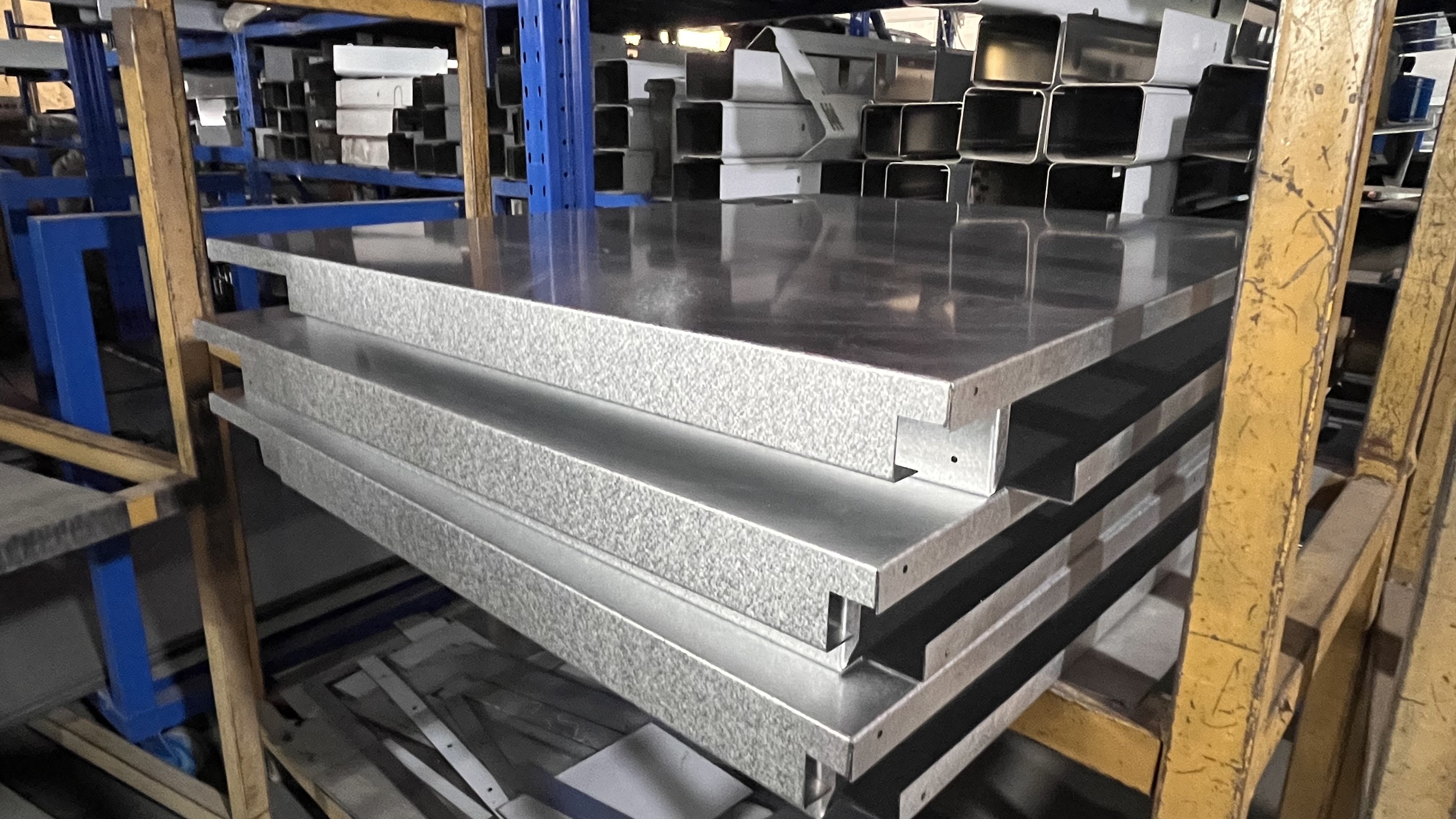

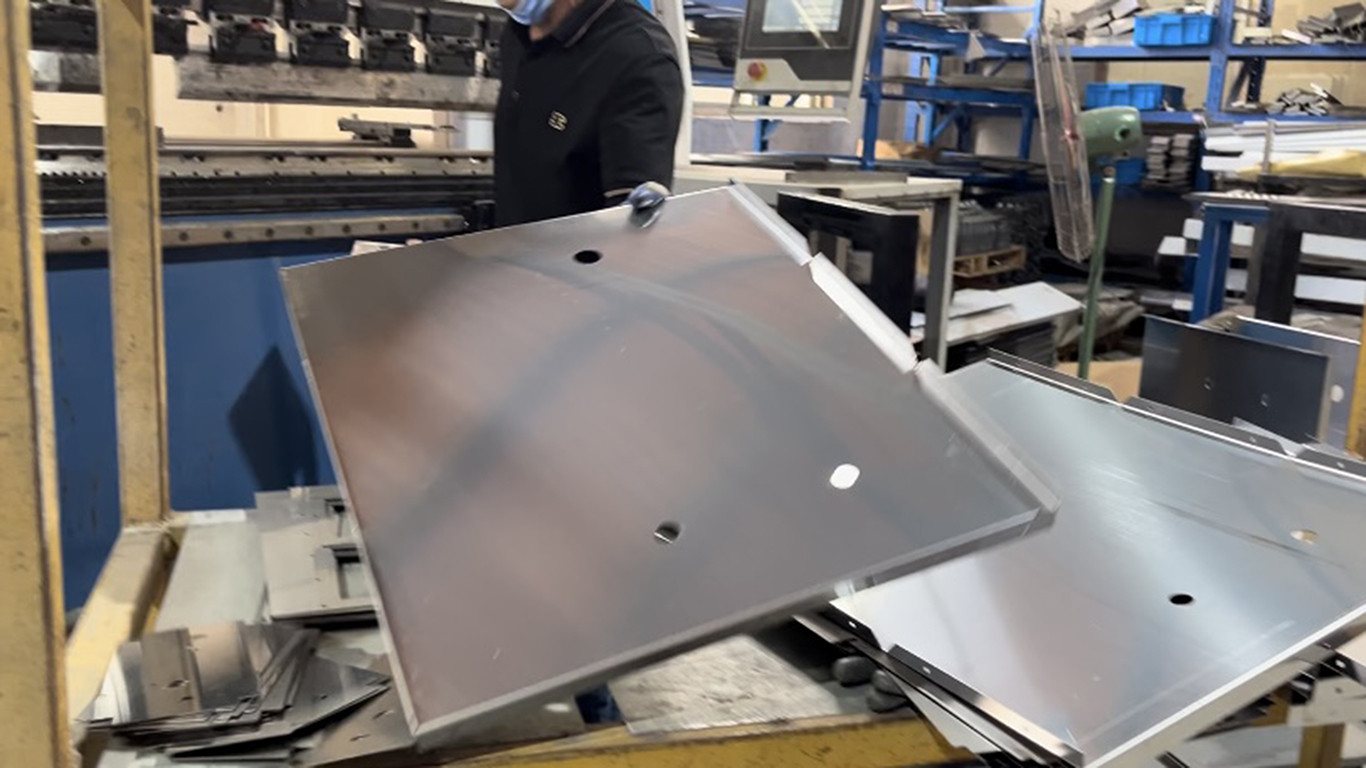

1、Sheet Metal: The Strong and Secure Framework of the Equipment

| Component | SamBake Standard | Common Low-Cost Market Configuration | Value Delivered to You |

| Outer Shell Sheet Metal | 430 stainless steel, ≥1.0mm thickness (national standard) | 201 stainless steel, ≤0.7mm thickness | Excellent high-temperature and corrosion resistance, ensuring long-lasting durability and shape retention in hot, humid kitchen environments; enhances professional brand image. |

| Structural Design | Exclusive internal folded reinforcement ribs design to prevent deformation common with traditional welded ribs | Traditional flat panels or simple welded ribs | Over 30% improved resistance to compression and deformation compared to traditional rib welding, ensuring the oven body remains stable and crack-free under prolonged high-temperature baking; maintains equipment precision and lifespan. |

| Cost Example | 430 steel costs ¥2,000–4,000 more per ton than 201 steel; upgrading thickness from 0.6mm to 1.0mm increases material cost by ¥400–900 per unit | Some manufacturers use painted steel panels to mimic stainless steel; looks similar short-term but rusts easily and coating peels off, especially causing returns on export orders, directly impacting your business reputation and profits. | SamBake insists on high-standard material selection to ensure your equipment is rock-solid from “frame” to “core,” completely eliminating failures, product contamination, and brand damage caused by inferior materials. |

| Comparison Aspect | SamBake Configuration | Common Low-Cost Configuration | Value Delivered to You |

| Structural Design | Dual-layer composite insulation system: outer layer made of high-density rock wool for basic insulation and structural support; inner layer near the baking chamber uses ceramic fiber blanket (aluminum silicate) for a second thermal barrier, significantly reducing heat transfer. | Mostly single-layer rock wool or glass wool, loosely packed with low density; shorter thermal resistance path leads to rapid heat loss. | Stronger heat retention, longer-lasting insulation, improved energy efficiency and safety. |

| Material Grade | Rock wool density ≥100kg/m³ for structural integrity and resistance to compression; ceramic fiber blanket rated for ≥1000°C, excellent thermal shock resistance. | Rock wool density typically 60–80kg/m³; prone to compression and deformation over time; rarely uses high-cost ceramic fiber materials. | Stable insulation structure, long-lasting heat resistance, and aging resistance. |

| Thermal Resistance | High total thermal resistance; outer shell temperature rise controlled within 40–50°C, ideal for extended operation. | Low thermal resistance; shell temperature rise often exceeds 60°C, wasting energy and posing safety risks. | Reduced energy waste, improved safety, and more comfortable for operator use. |

Energy Efficiency | Excellent heat retention; higher power utilization rate; saves 5–15% on electricity bills monthly on average—ideal for high-frequency operations like bakeries and central kitchens. | Significant heat loss; frequent reheating cycles raise energy usage and operational cost. | Lower long-term electricity consumption, reduced daily operational burden. |

Temperature Uniformity | Multi-layer insulation buffers minimize edge-to-center temperature variation, supporting consistent batch production—especially ideal for European breads, Danish pastries, mille-feuille, and other precision-demanding products. | Noticeable temperature fluctuation; uneven baking between center and edges, requiring frequent adjustments or corrective measures. | More consistent output, less waste, higher efficiency. |

Equipment Lifespan | Even internal heating and balanced thermal stress reduce the risk of metal expansion or cracking, extending equipment life. | Uneven heating and concentrated hot spots cause material fatigue, bulging, and deformation. | Fewer breakdowns, less frequent replacement, lower lifetime cost. |

Application Range | Standard configuration across all SamBake deck ovens, convection ovens, rotating rack oven and European bread ovens—suitable for bakeries to industrial kitchens. | Insulation upgrades typically limited to high-end or export models; others retain low-cost builds. | Wide adaptability to different production volumes and technical requirements. |

| Component | SamBake Specification / Brand | Common Low-Cost Alternative | Value Delivered to You |

| Heating Elements | Four heating rods per deck; approx. 5.5kW total power per layer. Even heat distribution and fast temperature rise. | Usually 2–3 rods per deck; uneven power distribution and slower heating. Some use low-cost wires prone to overheating or burnout. | Faster heating and more consistent temperature, reducing baking failures and downtime. |

| Temperature Sensor | High-sensitivity thermocouple with fast response and ±2°C accuracy. Compatible with multi-stage intelligent temperature control. | Basic thermal resistor with slow response and large deviation. | Precise temperature control, consistent product quality, less manual adjustment and waste. |

| Contactor | Uses top international brand Schneider for reliable switching, excellent heat and arc resistance. | Often low-cost local contactors with unstable performance and frequent overheating or sticking. | Lower failure rate, stable operation, reduced after-sales and maintenance costs. |

| Equipment | SamBake's Advantage | Value Delivered to You |

| Laser Cutting Machine | Imported Swiss Bystronic machine with high precision | Cutting accuracy up to ±0.2mm, burr-free and smooth edges, ensuring precise part dimensions for accurate assembly; improves overall aesthetics and durability. |

| Bending Equipment | Italian Salvagnini fully automated bending center | Capable of one-step complex angle forming, eliminating manual errors, increasing production efficiency and product consistency; guarantees precise oven structure, preventing deformation or heat leakage caused by inaccurate construction. |

| Welding Process | Multi-point welding combined with internal precision positioning fixtures | Ensures cavity remains deformation-free, pressure-resistant, and shockproof; strengthens structural integrity; prevents weak or cracked weld points, enhancing equipment stability and safety. |

Polishing | Automated polishing plus manual finishing | Ensures smooth and delicate exterior with no risk of cuts; enhances overall texture and leaves a professional, high-end impression. |

Core Advantage | We invest heavily in top-tier international processing equipment and rigorous manufacturing procedures, ensuring every SamBake oven achieves art-like precision and durability. More importantly, this enables us to meet complex customization demands with high accuracy and fast personalized production. | Low-cost products typically rely on outdated equipment and rough processes, resulting in large dimensional errors, rough appearance, and unstable structure. This not only affects aesthetics but shortens equipment lifespan, increases your maintenance costs, and may impact baking quality. |

SamBake: Your Behind-the-Scenes Customization Partner, Not Just a Equipment Supplier

Unlike many Chinese equipment manufacturers that focus on promoting their own brands for export, SamBake’s core business model is to be your customized partner on the path to brand success.

We don't emphasize the SamBake brand; we emphasize your brand!

We offer you unparalleled services including:

Comprehensive OEM/ODM customization support: Deeply understanding your brand philosophy and integrating it into equipment design.

Low minimum order quantity starting from just 1 unit: Reducing your upfront investment and trial costs, helping you start flexibly.

Extensive personalized customization:

Appearance customization: Exclusive colors, unique logos, and control panel language tailored to you.

Functional customization: Adjusting features according to your specific baking needs.

Energy type customization: Adapting to your local energy sources (electricity, gas, natural gas, etc.).

Structural and size customization: Meeting irregular space requirements and special production capacity needs.

We specialize in customized solutions in the following areas:

Small and micro bakery brands: Providing equipment perfectly tailored for small-batch, personalized production.

Private/customized and hybrid dessert shop equipment sets: Creating bespoke equipment that seamlessly integrates with your store style and product features.

Irregular space adaptation projects: Overcoming site limitations to maximize space utilization.

While many mainstream major brands hesitate to take on “non-standard orders” due to efficiency or cost concerns, SamBake leverages high-precision and fast-response personalized manufacturing capabilities to flawlessly meet these demands, helping our partners stand out in a competitive market and achieve differentiated advantages.

Our Pricing Philosophy: Fair, Sustainable, and Focused on Your Long-Term Success

SamBake never competes by offering the "lowest price". Our pricing strategy is built on a solid foundation of sustainable long-term partnerships and flexible project support.

Our core pricing principles:

Value-Driven: Our prices reflect the real value our products bring to you — such as higher efficiency, longer lifespan, lower energy consumption, and brand premium — rather than being based solely on manufacturing costs.

Partnership Focus: We view every customer as a valuable long-term market partner, not just a one-time transaction.

Strategic Support: We offer phased support pricing for promising distributors, emerging entrepreneurs, and high-potential projects with special needs.

We provide tiered pricing strategies tailored to different scales and needs:

Offering unit prices better than the local market.

Deep customization of features, capacity, and style to perfectly match your local positioning and product characteristics.

Helping you quickly build efficient production capacity, saving valuable time and capital.

Minimum order quantity starting from just 1 unit, greatly reducing your trial-and-error risks and financial burden.

Product adaptation services to assist market entry and accelerate your growth.

Access to phased support pricing after project feasibility evaluation, helping you navigate early development smoothly.

Flexible tiered pricing based on purchase volume, regional exclusivity, and brand plans.

Deep involvement in co-development, collaborating with SamBake to create new products tailored for local markets.

Priority project-based client support for large-scale engineering projects.

Additional Notes: Please look beyond the "visible costs" and carefully consider the following critical factors:

1、The hidden costs caused by poor product quality and unstable delivery — including rework, high maintenance expenses, and customer loss — often outweigh the savings of low-priced equipment.

2、The communication and procurement consolidation costs saved through long-term cooperation with SamBake, leading to more stable and efficient supply chains.

3、The outstanding energy-saving performance and extended service life of SamBake equipment significantly reduce your total cost of ownership, which is the real source of long-term profit.

Choosing SamBake: Your Assurance of Reliability and Growth

SamBake may not be the "cheapest" equipment on the market, but we know—and take pride in—the fact that our prices reflect our commitment to premium materials, exquisite craftsmanship, strong customization capabilities, and attentive service. This investment will ultimately translate into tangible long-term returns for you: stable production, outstanding product quality, and continuously growing brand value.

Choosing SamBake means more than just buying a piece of equipment; it means partnering with a strategic ally who truly supports your market expansion, brand building, and sustained business growth.

We look forward to working with those who are serious about making great products, establishing a brand, and pursuing long-term development—providing you with the most reliable, flexible, and practical support.